PRODUCT PARAMETERS

Description

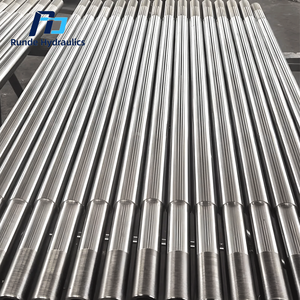

Introduction to Air shaft with inflating handle, inflating stick Air shaft fitting

Air shaft with inflating handle, inflating stick Air shaft fitting are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Air shaft with inflating handle, inflating stick Air shaft fitting

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Air shaft with inflating handle, inflating stick Air shaft fitting)

Specification of Air shaft with inflating handle, inflating stick Air shaft fitting

The Air Shaft with Inflating Manage and Stick deals a practical remedy for markets requiring trusted tooling for material winding. This product includes three almosts all: the blowing up take care of, blowing up stick, and air shaft fittings. The take care of is built for very easy operation. It enables users to readjust atmospheric pressure promptly. The style ensures a safe and secure hold. This lowers hand fatigue throughout extended usage. The inflating stick attaches directly to the air shaft. It moves air effectively to increase the shaft. This part is made from lightweight light weight aluminum. It stands up to deterioration in severe environments.

Air shaft fittings come in multiple dimensions. They match typical commercial demands. Each installation has a long lasting steel core. This protects against contortion under high pressure. The external layer utilizes rubber. It produces a limited seal versus air leaks. These installations work with shafts as much as 150 mm in size. They manage stress ranges from 0.3 to 0.8 MPa. This adaptability suits applications like printing, textiles, or movie processing.

The pumping up handle and stick operate together. They streamline the setup process. Customers affix the stick to the shaft. They pump air using the deal with. The system needs no additional devices. Maintenance remains simple. Cleansing involves cleaning surface areas with a dry towel. Lubrication is required only as soon as every six months.

Security functions include a pressure safety valve. It turns on if interior pressure goes beyond risk-free limits. This safeguards both tools and drivers. The shaft’s surface area has a non-slip structure. It keeps materials firmly in place during winding. Custom sizes are readily available. They accommodate makers with restricted room.

All parts fulfill ISO standards for industrial devices. Checking covers lots capability, air retention, and duplicated usage. The materials endure temperature levels from -20 ° C to 80 ° C. This ensures performance in different climates. Compatibility includes most pneumatic systems. Adapters are consisted of for unusual links.

The layout focuses on customer comfort. Substitute parts are standard. Downtime is minimized. Technical support is attended to installation questions. Training products information fixing steps. Guarantee covers production problems for 2 years.

(Air shaft with inflating handle, inflating stick Air shaft fitting)

Applications of Air shaft with inflating handle, inflating stick Air shaft fitting

Air shafts with inflating handles and blowing up sticks are crucial tools in markets requiring accurate control over material tension. These devices utilize compressed air to increase or get rapidly. The blowing up deal with enables customers to readjust the shaft’s size by hand. This makes it very easy to fit different core sizes without devices. The pumping up stick extends reach for hard-to-access locations. These functions conserve time and minimize physical pressure during setup.

In printing sectors, air shafts protected rolls of paper or film. The inflating take care of lets drivers lock products in place fast. Changes in between work occur smoothly. Downtime drops. The stick helps adjust shafts mounted high up on machinery. Workers remain safe by preventing ladders or overreaching.

Packaging lines rely on air shafts to hold plastic movies or labels. Uneven tension triggers wrinkles or misalignment. The inflating deal with makes sure also stress across the roll. This stops waste. Quick modifications keep production speeds high. The stick aids in repairing shafts inside slim devices. Maintenance comes to be easier.

Textile producing uses air shafts to manage textile rolls. Delicate products require mild handling. The take care of gives fine-tuned control. Operators stay clear of harmful materials throughout filling. The stick gets to shafts deep within weaving equipments. Rearranging takes secs. Effectiveness boosts.

In steel or plastic processing, air shafts safe and secure hefty coils. The inflating take care of assistances high-pressure demands. It takes care of thick materials without sliding. Employees change cores faster. The stick readjusts shafts in constrained rooms. Safety runs the risk of decline.

Automotive sectors apply air shafts for sticky tapes or insulation materials. Consistent stress ensures appropriate application. The handle enables rapid swaps in between item kinds. The stick gets to shafts behind equipment. Setup stays easy.

Air shafts with these fittings adjust to diverse environments. They simplify jobs throughout industries. Their style focuses on customer comfort. Productivity rises. Functional prices fall.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Air shaft with inflating handle, inflating stick Air shaft fitting

An air shaft with an inflating handle and stick helps hold rolls of material in place during manufacturing. It uses air pressure to expand or contract, fitting different roll sizes. The handle and stick make adjusting the shaft quick. Here are common questions about it.

What does an air shaft with an inflating handle and stick do? It grips material rolls tightly. Air pressure expands the shaft to match the roll’s inner size. The handle pumps air in or out. The stick helps reach the valve easily. This setup stops rolls from slipping during production.

How do I attach the inflating handle and stick to the air shaft? First, insert the handle into the shaft’s valve. Push until it locks. Connect the stick to the handle’s end. Turn the stick clockwise to secure it. Test by pumping air. If air leaks, check the connections again.

Why does the air shaft not stay inflated? Check for holes or cracks in the shaft. Ensure the handle and stick are tightly connected. Dirt in the valve might block air. Clean the valve with a cloth. If it still deflates, the seals inside might be worn. Replace them.

Is the inflating handle durable? The handle is made of strong plastic or metal. It lasts years with normal use. Avoid dropping it or forcing it into valves. The stick is usually steel or aluminum. Store both in a dry place to prevent rust.

Will this air shaft fit my machine? Measure your machine’s core size. Compare it to the shaft’s diameter range. Most shafts adjust between 2-6 inches. Check the handle and stick length. Some machines need longer sticks for hard-to-reach valves. Ask the seller for size details.

(Air shaft with inflating handle, inflating stick Air shaft fitting)

REQUEST A QUOTE

RELATED PRODUCTS

High Precision carbon steel bar 3 to 120mm diameter hard chrome plated linear shaft

SDS Drive Shafts 2201010W02 CS35 1.6L 5MT Left Half Shaft For Changan

waterjet high pressure pump swivel shaft 048127-1 for cnc water jet cutting machine

Multiple Types Custom Carbon Fibre Junior Graphic Design Golf Shaft

Customized Large Cnc Machining Forging Steel High Quality Big Spline Gear Shaft