PRODUCT PARAMETERS

Description

Introduction to Valve Expanding Rubber For Air Shaft Flat Tube

Valve Expanding Rubber For Air Shaft Flat Tube are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Valve Expanding Rubber For Air Shaft Flat Tube

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Valve Expanding Rubber For Air Shaft Flat Tube)

Specification of Valve Expanding Rubber For Air Shaft Flat Tube

The Shutoff Expanding Rubber for Air Shaft Apartment Tube is designed to make sure safe sealing and trusted performance in industrial applications. This part is made from high-grade artificial rubber. It combines adaptability with resilience to deal with repetitive expansion and contraction cycles. The rubber is crafted to withstand wear, abrasion, and chemical exposure, preserving honesty in extreme environments.

The product fits basic air shaft flat tubes with an internal diameter range of 20-100 mm. Custom-made dimensions are available for customized equipment. The rubber expands consistently when pressurized, developing a limited seal against the tube’s internal surface. This protects against air leak and maintains pressure throughout procedure.

Operating stress varieties from 0.3 to 0.8 MPa, appropriate for the majority of pneumatically-driven systems. The rubber maintains flexibility also under constant stress shifts. Temperature level resistance spans -30 ° C to 120 ° C, making sure capability in extreme cold or heat. It stands up to cracking or hardening with time.

Installment is straightforward. Clean the tube’s internal surface before putting the rubber. Apply modest air pressure to activate development. Inspect placement to avoid uneven securing. Normal examination is recommended to spot early signs of wear. Replace the rubber if surface splits or minimized elasticity are observed.

This product is perfect for printing equipment, packaging systems, and textile winding devices. It sustains high-speed procedures without endangering seal top quality. The rubber’s smooth surface decreases friction throughout tube rotation. This reduces energy loss and extends component life-span.

Product structure includes nitrile rubber (NBR) for oil resistance and additives for UV security. The style avoids sharp sides to avoid tube damage. Storage guidelines suggest maintaining the rubber in an amazing, dry area away from straight sunlight. Stay clear of contact with solvents or ozone resources before use.

Maintenance entails periodic cleansing with light detergent and water. Lubrication is unneeded due to the rubber’s self-lubricating buildings. Make certain compatibility with television material to stop chemical reactions. Examination stress settings after installation to verify ideal efficiency.

(Valve Expanding Rubber For Air Shaft Flat Tube)

Applications of Valve Expanding Rubber For Air Shaft Flat Tube

Valve Broadening Rubber for Air Shaft Flat Tube is a versatile element made use of across numerous markets. This product makes sure effective air movement control and pressure administration in systems including level tubes. Its design integrates adaptability with sturdiness, making it ideal for requiring settings.

In producing equipment, this rubber is important for sealing air shafts. It avoids air leakages during procedures, keeping consistent pressure. This stability enhances devices efficiency and reduces downtime. The material withstands wear from high-pressure cycles and temperature changes, ideal for heavy-duty applications.

The automobile sector relies upon this rubber for air shock absorber. It aids pump up and deflate flat tubes in car suspensions, changing ride height and comfort. The rubber’s strength guarantees it manages vibrations and roadway effects without weakening. This prolongs the lifespan of suspension elements contrasted to traditional products.

A/c systems utilize this rubber to safeguard connections in ductwork. It creates closed seals in between level tubes and vents, stopping power loss. The rubber adapts to thermal development, keeping seals intact despite temperature level shifts. This performance lowers power prices and sustains consistent environment control.

Packaging equipment employs the rubber to take care of air-driven procedures. It regulates rising cost of living in level tubes used to form packaging products. The accuracy of the rubber makes sure accurate pressure application, lowering product waste. Its reliability sustains high-speed assembly line without regular replacements.

Medical gadgets gain from this rubber in pneumatic systems. It controls airflow in devices like ventilators or compression therapy gadgets. The material meets stringent hygiene requirements, resisting wetness and chemical direct exposure. This ensures secure procedure in sensitive health care settings.

Aerospace applications demand materials that execute under severe problems. The rubber keeps seal honesty in air control systems for airplane. It endures quick pressure changes and temperature level extremes, critical for safety and security and performance throughout flights.

The product’s flexibility makes it a functional option for markets focusing on effectiveness and longevity. Its simple design minimizes installment intricacy, while durable performance decreases upkeep demands. Customers acquire lasting worth from reduced functional costs and improved system integrity.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Valve Expanding Rubber For Air Shaft Flat Tube

Valve expanding rubber for air shaft flat tubes helps create airtight seals in machinery. It expands when inflated, locking the tube in place. This prevents air leaks and ensures stable operation. Below are common questions about this product.

What does valve expanding rubber do? It seals air shaft flat tubes during use. The rubber expands when air pressure increases. This holds the tube securely in place. It stops air leaks and maintains pressure.

Will it fit any air shaft flat tube? Check the tube size and model first. Valve expanding rubber comes in different sizes. Using the wrong size may cause leaks. Contact the supplier to confirm compatibility.

How is the rubber installed? Clean the tube surface first. Insert the rubber into the designated area. Inflate it slowly to let it expand evenly. Avoid over-inflating to prevent damage. Follow the manufacturer’s guide for exact steps.

How long does the rubber last? It depends on usage and material quality. High-grade rubber lasts longer under heavy use. Regular inspections help spot wear early. Replace it if cracks or stiffness appear.

Where can I buy this product? Check with industrial hardware suppliers or the manufacturer’s website. Provide your tube specifications when ordering. This ensures you get the correct rubber size and type.

(Valve Expanding Rubber For Air Shaft Flat Tube)

REQUEST A QUOTE

RELATED PRODUCTS

Custom Long Crank shaft Drive Forging Large Eccentric shaft

YAMAHA Nozzle Shaft KLW-M711S-A0 KHY-M7107-A0X YSM10 SMT Nozzle for YAMAHA Pick and Place Machine

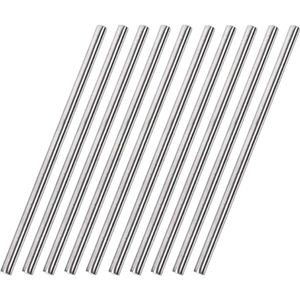

High-Quality Steel Hollow Shafts for 3D Printers – 50mm to 500mm Length, Customizable, 12mm, 16mm, 20mm Diameter, Hard Chrome Plated, Precision Bearing Components for Agricultural Machinery

High Quality Configures Coupling Shaft For Machinery Repair Shops

Custom Logo Cnc High Precision Ac Motor Shaft Sus304 Sus316L Sus410 Stainless Steel Motor Shaft