PRODUCT PARAMETERS

Description

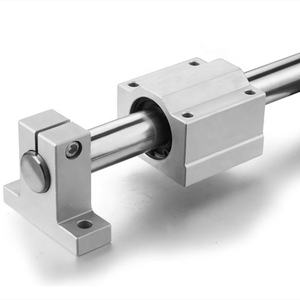

Introduction to Custom Precision Slender Shaft CNC Turning Machining Service Stainless Steel Rapid Prototyping Drilling Metal Material Capable

Custom Precision Slender Shaft CNC Turning Machining Service Stainless Steel Rapid Prototyping Drilling Metal Material Capable are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Custom Precision Slender Shaft CNC Turning Machining Service Stainless Steel Rapid Prototyping Drilling Metal Material Capable

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Custom Precision Slender Shaft CNC Turning Machining Service Stainless Steel Rapid Prototyping Drilling Metal Material Capable)

Specification of Custom Precision Slender Shaft CNC Turning Machining Service Stainless Steel Rapid Prototyping Drilling Metal Material Capable

Personalized Precision Slender Shaft CNC Turning Machining Solution offers tailored solutions for high-accuracy steel parts. This solution concentrates on creating slim shafts with tight tolerances. CNC transforming modern technology ensures constant results. The process fits stainless steel, light weight aluminum, brass, titanium, and various other metals. Stainless steel is a preferred option because of its toughness and rust resistance. Components made with this solution work well popular atmospheres.

Quick prototyping is readily available for quick design validation. This decreases growth time and expenses. Facility geometries are achievable with innovative CNC equipment. Boring procedures are integrated into the machining process. Accuracy holes are added to satisfy specific style requirements. Threading, grooving, and surface finishing options are included.

Steel material capabilities cover a vast array. Each product is selected based upon job demands. Longevity and efficiency are focused on. Personalization encompasses measurements, surface therapies, and set dimensions. Small to tool production runs are supported. Limited diameter control is maintained for slender shafts. This avoids flexing or deformation during machining.

Quality checks are executed at every stage. Advanced measuring tools confirm dimensional precision. Surface area roughness is tested to make certain smooth coatings. Knowledgeable specialists keep track of the process for consistency. Fast turnaround times satisfy immediate job target dates.

Industries like aerospace, automobile, medical, and robotics take advantage of this solution. Components consist of actuator poles, sensor pins, adapter shafts, and drive components. Layouts are optimized for capability and convenience of assembly.

The solution adapts to one-of-a-kind client requirements. Product certifications are given upon request. Technical support helps with style modifications. Cost-effective remedies equilibrium precision and affordability.

Stainless-steel models resist wear and chemical exposure. Heat-treated choices improve firmness for heavy-duty use. Lightweight steels like aluminum minimize general part weight. Boring precision ensures correct alignment for put together systems.

Machining parameters are changed for different metal qualities. This avoids tool wear and product damage. Efficient chip elimination preserves machining precision. Custom product packaging safeguards completed components throughout shipping.

Experienced designers manage complex project demands. Clear interaction guarantees client expectations are fulfilled. Examples are readily available for testing prior to complete production.

(Custom Precision Slender Shaft CNC Turning Machining Service Stainless Steel Rapid Prototyping Drilling Metal Material Capable)

Applications of Custom Precision Slender Shaft CNC Turning Machining Service Stainless Steel Rapid Prototyping Drilling Metal Material Capable

Customized accuracy slender shaft CNC transforming machining solutions use sensible remedies for markets needing exact steel parts. These solutions make use of sophisticated CNC modern technology to produce thin shafts with limited resistances. The procedure suits stainless steel and other steels. It supports quick prototyping, allowing quick testing of layouts prior to complete production.

Industries like aerospace, auto, and medical tools count on these services. Shafts made by doing this fit engines, pumps, or precision devices. Stainless-steel stands up to rust and deals with high anxiety. This makes it suitable for rough atmospheres. CNC turning makes sure each shaft satisfies exact requirements.

The machining process starts with an electronic design. Engineers program the CNC machine to cut steel into the desired form. The equipment rotates the material while tools remove unwanted. This technique attains smooth surface areas and accurate dimensions. Even intricate geometries are feasible.

Exploration is an essential part of the service. Holes can be included for screws, wires, or liquid channels. The CNC machine drills with accuracy, avoiding mistakes. This minimizes waste and accelerate production. Custom-made openings adjust components to details machinery or systems.

Steel materials like light weight aluminum, titanium, or brass are additionally compatible. Each material has unique benefits. Aluminum is lightweight. Titanium supplies stamina. Brass resists wear. The solution selects the very best material for the application.

Rapid prototyping lets customers test layouts early. Modifications are made promptly right away jobs. This saves time and prices. Personalized shafts can be fine-tuned until they fulfill all needs.

The solution sustains little and large manufacturing runs. Short runs are cost-effective for models. Huge runs keep uniformity across countless parts. Limited high quality checks ensure every shaft does dependably.

Stainless-steel stays preferred for its longevity. It operates in food handling, chemicals, or outside equipment. CNC machining handles its toughness without losing accuracy. Finished shafts need marginal sprucing up or coating.

These machining solutions adjust to one-of-a-kind demands. Clients offer requirements, and specialists supply tailored solutions. The focus gets on performance, speed, and precision. Industries obtain components that integrate flawlessly right into their systems.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Custom Precision Slender Shaft CNC Turning Machining Service Stainless Steel Rapid Prototyping Drilling Metal Material Capable

1. What materials do you work with for custom precision shafts?

We mainly use stainless steel. Other options include aluminum, brass, titanium. All materials meet industry standards. They ensure durability, corrosion resistance. Metal properties suit high-stress applications. We confirm material quality before machining.

2. How precise are your CNC turning services?

Tolerances reach ±0.01 mm. Advanced CNC machines handle slender shafts. Tight control avoids bending or warping. Precision tools maintain consistency. Each part undergoes measurement checks. This guarantees exact specifications.

3. Can you make rapid prototypes for testing?

Yes. Prototypes are ready in 5-7 days. CNC turning creates functional samples quickly. Adjustments are possible based on feedback. No extra costs for design tweaks. Rapid prototyping speeds up product development.

4. Do you offer custom drilling services for metal parts?

Drilling is included. Hole sizes range from 0.5 mm to 20 mm. Depth depends on shaft dimensions. Accurate positioning avoids errors. Burr-free finishes ensure smooth edges. Complex patterns are no problem.

5. How do you ensure quality in stainless steel machining?

Strict quality checks happen at every step. Tools are calibrated daily. Final inspection uses CMM and micrometers. Surface roughness tests confirm finishes. Certifications like ISO 9001 guide our process. Defective parts get rejected immediately.

(Custom Precision Slender Shaft CNC Turning Machining Service Stainless Steel Rapid Prototyping Drilling Metal Material Capable)

REQUEST A QUOTE

RELATED PRODUCTS

Lower Telescopic Aluminium Telescopic Aluminium Linear Guide Rail Shaft for Water Pipe Plumbing

7L0 521 101 H Driveshaft Prop Shaft Fit For VW Touareg Porsche Cayenne Drive Shaft 7L0521101H

Customized Shaft OEM Precision CNC Automatic Lathe Aluminum Brass Stainless Steel Turning part pin shaft For CNC Machined

DIN981 Standard Steel Round Slotted Shaft Nut, M20~M80 Locknuts for use with rolling bearings

tige en acier inoxydable Aisi 201 303 430 317 416 410 420 904l 316l 310s Round Stainless Steel Shaft 316 304 round Bar Rod