PRODUCT PARAMETERS

Description

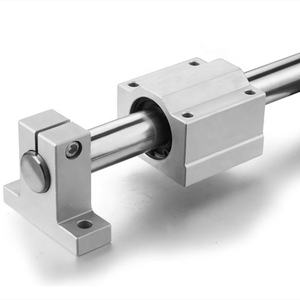

Introduction to 304 steel shafts stainless steel linear shafts

304 steel shafts stainless steel linear shafts are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of 304 steel shafts stainless steel linear shafts

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(304 steel shafts stainless steel linear shafts)

Specification of 304 steel shafts stainless steel linear shafts

304 steel shafts are stainless steel linear shafts designed for precision and longevity in commercial applications. These shafts utilize 304-grade stainless-steel recognized for its corrosion resistance and toughness. The product stands up to moisture, chemicals, and environmental variables, making it appropriate for rough problems. The steel has chromium and nickel, boosting its capacity to endure rust and put on in time. These shafts preserve performance in high-stress environments without weakening.

The surface area finish of 304 steel shafts is smooth, decreasing rubbing during procedure. Precision machining guarantees constant dimensions and straightness for trusted alignment in machinery. The shafts deal with straight bearings, guides, and motion systems, giving steady motion in automatic devices. Usual applications consist of CNC machines, clinical tools, packaging systems, and robotics.

304 stainless steel direct shafts take care of hefty tons due to their high tensile strength. They sustain vibrant and fixed loads without bending or warping. The hardness of the product reduces surface area damages from duplicated usage. These shafts run efficiently across a large temperature range, maintaining performance in extreme heat or cold.

Sizes vary to fulfill various industrial needs. Criterion diameters range from 5mm to 50mm, with lengths customizable for particular tasks. The shafts undertake top quality checks to make certain compliance with industry standards. Qualifications like ISO or ASTM might apply depending on maker techniques.

Personalization alternatives include unique coverings or therapies for added protection. Some shafts feature ground finishes for tighter tolerances. Lubrication grooves or threaded ends can be added for less complicated combination into existing systems. Technical support is typically readily available to help select the appropriate shaft configuration.

Maintenance needs are reduced due to the product’s fundamental residential properties. Normal cleaning with non-abrasive materials maintains the surface. Evaluations for debris or misalignment assistance extend life span. Correct installation makes certain ideal performance and minimizes downtime.

304 steel shafts use an affordable solution for long-lasting use. Their resistance to corrosion and mechanical anxiety lowers replacement frequency. Industries focus on these shafts for projects demanding reliability and precision. Compatibility with various elements makes them functional throughout different equipment types.

(304 steel shafts stainless steel linear shafts)

Applications of 304 steel shafts stainless steel linear shafts

304 stainless steel direct shafts are extensively used in lots of markets due to their strength, corrosion resistance, and longevity. These shafts work well in environments where wetness, chemicals, or high temperatures exist. Their smooth surface coating ensures reduced rubbing, making them excellent for accuracy movements.

In commercial machinery, 304 steel shafts are common in conveyor systems, robot arms, and CNC equipment. They deal with heavy loads without flexing. Their resistance to rust maintains them reliable in manufacturing facilities with high humidity or direct exposure to liquids. Upkeep is basic, lowering downtime in assembly line.

The auto market makes use of these shafts in steering systems, suspension elements, and transmission parts. They endure resonances and tension during car operation. Corrosion resistance is important here, especially in regions with road salt or extreme weather. The material’s strength guarantees long-term efficiency under continuous use.

Food and beverage handling tools often counts on 304 stainless-steel shafts. They meet hygiene requirements because they resist bacterial growth and are simple to clean. These shafts are utilized in mixers, loading equipments, and packaging systems. They do not react with acids or cleaning up representatives, ensuring item security.

Clinical devices like medical tools and imaging makers make use of these shafts for accuracy and integrity. The non-reactive nature of stainless-steel prevents contamination. Smooth procedure is vital in equipment needing accurate movements, such as flexible beds or analysis instruments.

Marine and outdoor applications benefit from 304 steel shafts. Saltwater, rain, and UV direct exposure do not deteriorate them swiftly. They are used in boat parts, solar trackers, and farming machinery. Their capability to stand up to matching and rust prolongs service life in tough problems.

These shafts are likewise located in 3D printers and automated systems. Accuracy is key right here, and the smooth surface area makes sure consistent motion. Reduced maintenance requirements make them economical for high-usage settings.

304 stainless steel linear shafts adapt to both high-stress industrial jobs and delicate clinical operations. Their convenience originates from an equilibrium of mechanical toughness and corrosion resistance. Industries pick them for dependability, reducing replacement costs and boosting performance.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of 304 steel shafts stainless steel linear shafts

What are 304 steel shafts made of? They are made of 304 stainless steel. This steel has chromium and nickel. These elements make it resist rust and corrosion. It works well in wet or humid places. The material is strong and lasts long. It is a common choice for industrial parts.

Can 304 steel shafts handle heavy loads? Yes. They are strong and durable. They work for machines needing steady movement. They handle moderate stress well. Avoid using them in extreme high-pressure situations. Check load limits before installing them.

Do 304 steel shafts rust easily? No. The chromium in the steel forms a protective layer. This layer stops rust and corrosion. They work in damp or chemical environments. Clean them regularly to keep the layer intact.

Are 304 steel shafts easy to maintain? Yes. They need little upkeep. Wipe them with a clean cloth. Remove dirt or debris. Avoid harsh chemicals. Lubricate them if the application requires smooth movement.

What industries use 304 steel linear shafts? Many industries use them. Food processing uses them because they resist corrosion. Medical equipment uses them for precision. Automotive systems use them for durability. They are common in packaging and printing machines too.

(304 steel shafts stainless steel linear shafts)

REQUEST A QUOTE

RELATED PRODUCTS

HP-601Rotaries Shaft 1/4″, Diameter: 5/8″,15.8mm , Width/Length: 5/8″, 15.8mm, Bore: 1/4″, 6mm Grits: 330

Mountain Road Snow Bicycle Barrel Shaft Hub Conversion Shaft 15 Turn 9 100MM Aluminum Alloy Quick Release Conversion Shaft

BS-G-020 Original Factory Universal Washing Machine Gear Box Reducer Shafts for Samsung

Kaishan down the Hole Drilling Machine Accessory Zhigao Power Head Central Gear Shaft Rotary Shaft for Ore Mining

Factory Direct s High Hardness Good Transmission Rate Engine Camshaft Gear For Loaders