PRODUCT PARAMETERS

Description

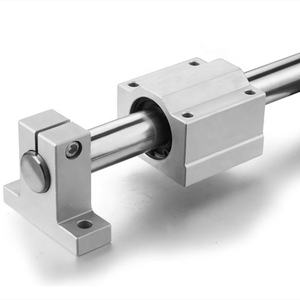

Introduction to 400 machines customized spline shaft AS9100 IATF16949 ISO13485 spline shaft transmission carbon shaft

400 machines customized spline shaft AS9100 IATF16949 ISO13485 spline shaft transmission carbon shaft are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of 400 machines customized spline shaft AS9100 IATF16949 ISO13485 spline shaft transmission carbon shaft

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(400 machines customized spline shaft AS9100 IATF16949 ISO13485 spline shaft transmission carbon shaft)

Specification of 400 machines customized spline shaft AS9100 IATF16949 ISO13485 spline shaft transmission carbon shaft

We produce 400 custom-made spline shafts. These shafts meet strict top quality requirements: AS9100, IATF16949, ISO13485. They are developed for dependable power transmission. The material is top-quality carbon steel. Carbon steel offers superb toughness. It stands up to hefty tons. It likewise stands up to wear gradually. This ensures a lengthy life span.

Each shaft is precisely machined. The spline teeth are reduced precisely. This ensures a perfect fit. The fit is crucial for smooth procedure. Vibration is minimized. Power transfer is reliable. You obtain regular efficiency. We equipment shafts to your specific illustrations. Measurements are important. We follow your specs precisely. Size, size, tooth account, and resistance are all matched. We do not jeopardize on precision.

These qualifications show our dedication. AS9100 covers aerospace high quality. IATF16949 is for auto excellence. ISO13485 makes sure clinical device reliability. We adhere to these systems daily. Our processes are regulated and recorded. Every shaft goes through complete evaluation. We examine measurements and surface finish. We verify material residential or commercial properties. Top quality is validated prior to delivery. You get parts you trust.

These spline shafts send torque effectively. They connect rotating components securely. Typical uses consist of airplane systems. They work in automobile transmissions. They are vital in precision medical equipment. Industrial equipment counts on them. Robotics applications require their precision. They handle requiring atmospheres. Broadband and hefty tons are taken care of. Our shafts give a trustworthy link.

(400 machines customized spline shaft AS9100 IATF16949 ISO13485 spline shaft transmission carbon shaft)

Applications of 400 machines customized spline shaft AS9100 IATF16949 ISO13485 spline shaft transmission carbon shaft

Our 400 machines construct personalized spline shafts. They are carbon shafts. These shafts relocate power reliably. They fit flawlessly into equipments or couplings. This specific fit means power moves without slipping. It additionally indicates less vibration. This matters for tough jobs. Our shafts fulfill AS9100, IATF16949, and ISO13485 requirements. This reveals top quality and security. We develop them for several requiring fields.

Aerospace requires these shafts. Airplane systems require perfect reliability. Our shafts handle strong turning forces. They operate in landing gear systems. They work in flight controls. The AS9100 accreditation proves they satisfy difficult aerospace policies. Failure is not an option right here.

Automotive uses them also. Particularly high-performance and electrical cars. These vehicles need effective power transfer. Our shafts assist make automobiles faster. They aid automobiles utilize power far better. They last much longer under stress and anxiety. The IATF16949 requirement implies we follow rigorous automobile market processes. Every shaft is developed right.

Medical tool manufacturers trust our shafts. Precision clinical devices require smooth, specific activity. Think medical robots. Assume imaging devices like MRI machines. Our shafts supply that smooth activity. They are developed cleanly and securely. The ISO13485 accreditation ensures this for clinical use. Individual safety relies on reliable parts.

Industrial makers rely on these shafts. Hefty equipment in factories utilizes them. Power generation devices uses them. Robotics uses them. These areas need shafts that withstand consistent heavy loads. They require shafts that last. Our carbon spline shafts deliver that toughness. They maintain makers running longer. They lower downtime for repair services.

These shafts fix connection problems. They use a strong link in between rotating components. They deal with high torque. They take care of broadband. Customization is vital. We make shafts to your precise dimension and tooth specs. This ensures the very best suitable for your device. It makes certain the very best efficiency. Our accreditations ensure our top quality systems. You get a component constructed for your particular tough job. It will certainly carry out. It will certainly last.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of 400 machines customized spline shaft AS9100 IATF16949 ISO13485 spline shaft transmission carbon shaft

What material is best for high-strength spline shafts?

Carbon steel is the top choice. It offers great strength and durability. These shafts handle heavy loads and tough conditions well. Carbon steel also machines precisely for perfect spline teeth. This ensures smooth power transfer in transmissions.

Why do certifications like AS9100 matter?

AS9100, IATF 16949, ISO 13485 are critical. They prove the maker follows strict quality rules. AS9100 is for aerospace safety. IATF 16949 is for automotive reliability. ISO 13485 covers medical devices. These certifications mean the shaft meets high industry standards consistently.

Can you make custom spline shafts?

Yes. We specialize in custom spline shafts. We adjust the length, diameter, number of teeth, and pressure angle. Tell us your machine’s exact needs. We design and build the spline shaft to fit perfectly.

How do you ensure spline shaft quality?

Quality control is thorough. Every step is checked. We use precision CNC machining for accuracy. Each spline shaft gets measured carefully. We inspect dimensions, tooth profile, and surface finish. Testing confirms strength and performance. Our certified systems guarantee reliable parts.

What about delivery times?

Delivery depends on complexity and order size. Standard designs ship faster. Highly customized shafts need more machining time. We give you a clear timeline upfront. We focus on quick turnaround without sacrificing quality. We keep you informed on progress.

(400 machines customized spline shaft AS9100 IATF16949 ISO13485 spline shaft transmission carbon shaft)

REQUEST A QUOTE

RELATED PRODUCTS

CRAFT Turbo TD03 Turbine wheel shaft 49131-07030 49S31-07005 11657593015 for BMW 135i 335i 535i

18Crnimo6 precision CNC steel materials Spline Gear Shaft for Industry gearbox

Chrome Silver Plating Steel Single Bend Golf Shaft for Putter

Custom Stainless Steel Small Linear Shaft Motor Drive Shaft Cylindrical Solid Straight Metal Dowel Shaft Pin For Connecting

Custom Logo Cnc High Precision Ac Motor Shaft Sus304 Sus316L Sus410 Stainless Steel Motor Shaft