PRODUCT PARAMETERS

Description

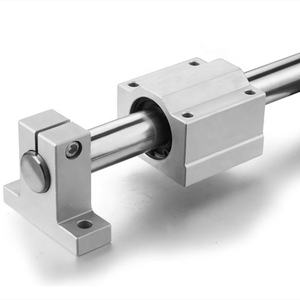

Introduction to Carbon shaft flexible shaft large diameter shaft

Carbon shaft flexible shaft large diameter shaft are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Carbon shaft flexible shaft large diameter shaft

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Carbon shaft flexible shaft large diameter shaft)

Specification of Carbon shaft flexible shaft large diameter shaft

Carbon shafts are strong. Carbon shafts are lightweight. Carbon fiber materials make them. Carbon shafts resist corrosion well. Carbon shafts handle high stress. Carbon shafts perform in demanding environments. Aerospace uses them. Automotive uses them. Sports equipment uses them. Specific diameters vary. Lengths are customizable. Wall thickness matters for strength. Stiffness is a key feature. Torsional rigidity is high. Carbon shafts offer design flexibility. Engineers like them.

Flexible shafts transmit torque. Flexible shafts transfer rotation. Flexible shafts go around corners. Flexible shafts reach tight spaces. Flexible shafts connect drivers to driven parts. Machinery uses them. Power tools use them. Medical devices use them. The core is often steel wire. The core is wound tightly. Protective outer layers shield the core. Flexible shafts bend easily. Flexible shafts twist effectively. Flexible shafts maintain power transmission. Different diameters are available. Different lengths are available. The bending radius is important. The maximum RPM rating matters. Flexible shafts handle high speeds. Flexible shafts are durable. Flexible shafts are reliable.

Large diameter shafts are heavy-duty. Large diameter shafts are structural. Large diameter shafts carry big loads. Large diameter shafts support rotating machinery. Large diameter shafts are found in industrial gear. Large diameter shafts are in turbines. Large diameter shafts are in generators. Large diameter shafts are in pumps. Large diameter shafts are in conveyors. Steel is a common material. Steel provides great strength. Steel handles high torque. Steel handles large bending moments. Sizes range widely. Sizes go from several inches. Sizes go up to many feet. Surface finish is critical. Surface finish affects bearing life. Surface finish affects seal performance. Precision machining is essential. Precision machining ensures balance. Precision machining ensures straightness. Large diameter shafts are custom made. Large diameter shafts meet exact needs. Large diameter shafts handle tough jobs.

(Carbon shaft flexible shaft large diameter shaft)

Applications of Carbon shaft flexible shaft large diameter shaft

Shafts are everywhere in machines. They move power from one place to another. Different jobs need different shafts. Carbon shafts are a great choice for many uses. They are very light but also very strong. This makes them perfect where weight matters a lot. Think about things like drones or high-performance cars. A lighter shaft means the whole machine can be lighter. Carbon shafts also resist twisting under load. This keeps power delivery smooth. They don’t rust like steel either. This is good in wet places or outdoors. Flexible shafts work differently. They are made to bend. This lets them send power around corners. You need this in tight spots. Tools like dental drills use flexible shafts. The dentist’s handpiece connects to the motor with one. Mechanics use them for hard-to-reach bolts. Flexible shafts handle the rotation even while bent. Large diameter shafts handle big jobs. They carry heavy loads and high torque. You see them in big industrial machines. Mining equipment uses large shafts. So do ships for their propeller systems. Power plants rely on them for generators. These shafts are tough. They are built to last under constant stress. The bigger size spreads the force out. This prevents bending or breaking. Choosing the right shaft matters. It depends on the power needed. It depends on the space available. It depends on the weight limits. Carbon shafts offer lightness and strength. Flexible shafts solve tricky routing problems. Large diameter shafts deliver serious power. All three types keep machines running every day. They are vital parts we often don’t see.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Carbon shaft flexible shaft large diameter shaft

What are carbon shaft flexible shafts with large diameters? They are strong, bendable rods made from carbon fiber. People use them when they need power transfer over distances or around obstacles. Large diameters handle more torque. This means they can drive bigger equipment.

Why pick carbon fiber for these shafts? Carbon fiber is light but very strong. It does not rust. It lasts longer than steel in tough conditions. It handles high speeds well. Carbon shafts also dampen vibrations better. This protects connected machines.

How does a large diameter help? A bigger shaft moves more power. It twists less under heavy loads. This gives more control. Large diameters also handle higher rotation speeds safely. They are good for demanding industrial jobs.

Where do people use large diameter carbon flexible shafts? You find them in factories. They drive pumps, mixers, or conveyors. Marine uses are common too, like for boat steering. They work in construction equipment. Anywhere space is tight but power is needed, they help.

How do I care for a large carbon flexible shaft? Keep it clean. Dirt and grit wear it out faster. Check for damage often, like fraying. Lubricate it as the maker says. Don’t bend it too sharply; follow the minimum bend radius. Store it straight when not in use.

(Carbon shaft flexible shaft large diameter shaft)

REQUEST A QUOTE

RELATED PRODUCTS

Flexible shaft with stable quality shaft

Custom 35crni2mov Heavy-duty Drive Gear Shaft Large Module Gear Shaft

Factory High Quality Auto Transmission Systems Drive Shaft OEM 3815A137

High Quality Carbon fiber shaft , Maple butt 58″ 4 color 1/2-pc Unilock Joint Billiard Pool Cue for

JeaSnn CNC small brass double threaded 20mm metal pin shaft carbon steel custom round shaft precision 304 stainless steel shaft