PRODUCT PARAMETERS

Description

Introduction to Customized cnc machine anodized aluminium ring design machining long shaft screw thread shaft turning parts

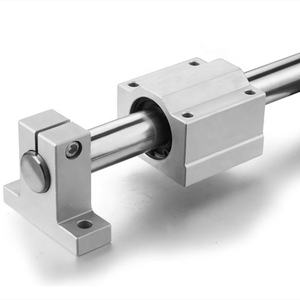

Customized cnc machine anodized aluminium ring design machining long shaft screw thread shaft turning parts are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Customized cnc machine anodized aluminium ring design machining long shaft screw thread shaft turning parts

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Customized cnc machine anodized aluminium ring design machining long shaft screw thread shaft turning parts)

Specification of Customized cnc machine anodized aluminium ring design machining long shaft screw thread shaft turning parts

Personalized CNC machine anodized light weight aluminum ring layout machining provides accurate solutions for industrial components. These parts include long shaft screw thread shafts and transforming parts made through progressed CNC modern technology. The procedure ensures high precision for intricate geometries and tight resistances. Anodized aluminum rings use sturdiness and resistance to deterioration. The light weight aluminum surface undertakes an electrochemical therapy to enhance hardness and aesthetic charm. Several color alternatives are readily available for customized orders.

Long shaft screw thread shafts are developed for applications calling for stamina and accuracy. CNC machining produces regular threads with precise pitch and deepness. These shafts take care of hefty loads and rotational pressures in machinery. Materials like stainless-steel or titanium are used for included toughness. Customized sizes and diameters fulfill details job needs. Strings are checked for smooth interaction with mating parts to prevent wear.

CNC turning parts are produced using turrets to form raw materials right into completed elements. The process attains smooth surface area finishes and dimensional precision. Components include ports, spacers, and fittings for mechanical systems. CNC programs enables rapid changes for style modifications. Examining makes sure each part matches technological illustrations before shipment.

All parts undertake quality checks for issues or variances. Measurements utilize devices like calipers and micrometers. Pressure tests verify performance under functional stress and anxiety. Plated finishes are examined for uniformity and adhesion. Personalized orders get in-depth documents with requirements and material certifications.

These services satisfy sectors like auto, aerospace, and robotics. Designers benefit from rapid prototyping to major production. Preparations differ based upon intricacy and order quantity. Technical support aids with design optimization for manufacturability. Affordable options stabilize high quality and budget demands.

Products are sourced from trusted providers to ensure consistency. Machining facilities employ skilled operators and modern equipment. Environmental controls preserve stable conditions throughout manufacturing. Product packaging secures components throughout delivery to stop damages. Revisions are fit to address client comments.

(Customized cnc machine anodized aluminium ring design machining long shaft screw thread shaft turning parts)

Applications of Customized cnc machine anodized aluminium ring design machining long shaft screw thread shaft turning parts

Custom-made CNC maker plated light weight aluminum ring design machining serves numerous industries calling for precision and resilience. These parts manage intricate tasks in aerospace, auto, medical devices, and electronic devices. CNC machining guarantees limited resistances and smooth surfaces vital for high-performance applications. Plated aluminum rings withstand corrosion and wear, making them suitable for environments revealed to moisture or chemicals. The process allows personalized sizes and shapes to fit particular tools demands.

Lengthy shaft screw thread production counts on CNC transforming for accuracy and uniformity. These shafts transfer motion or support revolving elements in equipment. Strings cut through CNC devices maintain precise pitch and depth, making sure trustworthy connections. Industries like robotics and automation depend on these parts for smooth operation. Custom-made threads adapt to one-of-a-kind designs, decreasing setting up mistakes.

Shaft turning components made with CNC modern technology suit applications requiring stamina and accuracy. Automotive systems make use of these parts in transmissions and engines. CNC makers create complicated geometries, such as grooves or undercuts, without hands-on modifications. This reduces manufacturing time while enhancing component quality. Medical equipment suppliers make use of turned shafts for gadgets requiring clean and sterile, non-reactive products.

Threaded shafts generated by means of CNC transforming take care of heavy lots in building and commercial machinery. Custom strings prevent loosening up under resonance, enhancing security. The process enables materials like stainless steel or titanium for extra toughness. Electronic devices manufacturers make use of smaller sized threaded shafts in portable tools, making sure safe fastening in minimal areas.

Plated light weight aluminum rings find usage in customer products like watches or sports equipment. The coating includes shade or enhances grasp without endangering steel honesty. CNC machining enables complex patterns for attractive or practical functions. These rings likewise offer in electric systems as conductive or protecting elements.

CNC-machined parts adapt quickly to create adjustments, supporting prototyping and automation. Industries gain from decreased waste and faster turnaround times. Customized options attend to special difficulties, boosting efficiency throughout applications. The mix of anodized finishes and precise machining prolongs item lifespans popular conditions.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Customized cnc machine anodized aluminium ring design machining long shaft screw thread shaft turning parts

What materials are used for CNC-machined anodized aluminum rings?

Aluminum is the primary material. It is lightweight, corrosion-resistant, and easy to machine. Anodizing adds a protective oxide layer. This improves durability and allows color customization. Other materials like stainless steel or titanium are options for specific needs.

How precise are CNC-machined threaded shafts?

Tight tolerances are achievable. CNC machines handle precision down to ±0.005 mm. Thread pitch and diameter are controlled accurately. This ensures compatibility with nuts or mating parts. Consistency is maintained across large production batches.

Can custom designs be machined for unique applications?

Yes. CAD files or sketches are used to program the CNC machines. Complex geometries, grooves, or engravings are possible. Modifications to shaft length, thread type, or ring diameter are standard. Prototypes are available for testing before full production.

What factors affect the cost of CNC-machined parts?

Material choice impacts price. Aluminum is cost-effective. Complex designs require longer machining time. Surface treatments like anodizing add expense. Order quantity lowers per-unit costs. Lead time is shorter for simpler projects.

How does anodizing improve aluminum parts?

Anodizing prevents corrosion and wear. The surface becomes harder and more scratch-resistant. Colors stay vibrant without fading. Electrical insulation properties are enhanced. Maintenance needs are reduced over the part’s lifespan.

(Customized cnc machine anodized aluminium ring design machining long shaft screw thread shaft turning parts)

REQUEST A QUOTE

RELATED PRODUCTS

Open Positioning Hole Type STHWRBK STHWRK SSTHWRK Fixed Bearing Seat 12MM 16MM 20MM 25MM 30MM Guide Shaft Supports

For TRANSIT Original drive shaft mounting bracket Centre bearing part CC114826AA 1810012 6649122

Industrial Power Transmission Worm Shaft Right Angle Gearbox

Automotive cv joint parts drive shaft for toyota hilux 43460-80033 43460-09V10 43460-80035

16S2530TO 16S2230TD truck marine gearboxes spare parts cylinder shaft 1325334017 1325 334 017