PRODUCT PARAMETERS

Description

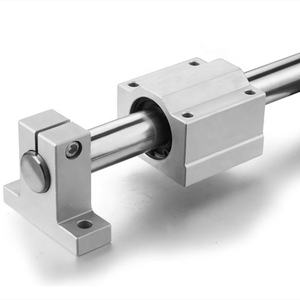

Introduction to Factory Fan Motor shaft

Factory Fan Motor shaft are important components in mechanical systems used to support rotating parts (such as gears, pulleys or sprockets) and transmit torque. They play a key role in mechanical equipment by connecting the power source with the working parts to ensure the effective transmission of power.

Characteristic advantages of Factory Fan Motor shaft

High precision: adopting precision machining technology ensures the size and shape accuracy of the shaft and improves the transmission efficiency.

High strength: made of high-quality materials with good tensile, compressive and wear-resistant properties.

Reliability: After strict quality control, it ensures stable operation for a long time.

Versatile design: A variety of specifications and types are available to suit different applications.

Easy maintenance: the structure is designed for easy installation and repair, reducing maintenance costs.

(Factory Fan Motor shaft)

Specification of Factory Fan Motor shaft

This part connects the follower blades to the motor itself. It transfers the motor’s rotating power straight to the follower. The shaft needs to be strong. It should take care of continuous turning and stress. We make use of state-of-the-art carbon steel. This product offers superb toughness. It withstands bending or damaging under lots.

The shaft size is vital. It must fit specifically into the electric motor bearings and the follower hub. Common sizes vary from 12mm to 25mm. Specific measurements depend on the electric motor power and fan size. Length is additionally essential. It should be long sufficient to securely reach through the follower hub. It must not be too long. Too much size can create vibration.

We equipment the shaft to very tight tolerances. This makes certain best roundness and straightness. Even little discrepancies trigger inequality. Inequality results in resonance and sound. Resonance harms bearings and reduces motor life. Accuracy machining stops this.

The shaft surface is smooth. We grind it finely. This smooth finish reduces rubbing inside the bearings. Lowered rubbing means less warmth. Much less warm implies better performance and longer bearing life. Some shafts feature keyways. Keyways are ports cut along the shaft. They accept steel tricks. Keys lock the fan center firmly onto the shaft. This stops slippage. Various other shafts make use of tapered layouts or securing collars for protected add-on.

Shaft ends are usually threaded. Threads permit nuts or other equipment to secure the fan. We protect the shaft versus rust. Deterioration damages the steel. It can cause seizing in bearings. Typical protection consists of zinc plating or special finishings. The shaft should line up flawlessly with the motor blades. Perfect alignment ensures smooth, quiet procedure. Proper shaft style is fundamental for dependable follower performance. It directly impacts electric motor effectiveness and durability.

(Factory Fan Motor shaft)

Applications of Factory Fan Motor shaft

Factory follower motor shafts transform fan blades. This easy component matters a lot. Manufacturing facilities require great air motion. Shafts make that happen.

Ventilation is vital. Stagnant air really feels bad. Workers need fresh air. Fan shafts spin blades to pull fresh air within. They press old air out. This maintains the air clean inside huge structures.

Equipments fume. Warmth harms equipments. Fan shafts drive cooling down followers. These fans blow air over hot devices. Motors, electronic devices, and gearboxes stay cooler. This prevents malfunctions. Equipments last longer.

Dirt and fumes are troubles. They are harmful. They can be hazardous. Extraction systems utilize powerful followers. The electric motor shaft powers these followers. It draws unclean air away from work areas. Cleanser air is safer for every person.

Product handling needs air also. Sharing systems often make use of air circulation. Follower shafts power blowers. These blowers relocate lightweight materials like grains or plastic pellets through pipelines. This relocates stuff efficiently.

Procedures need exact temperature levels. Stoves, dryers, and chemical vats require control. Follower shafts drive flow followers. These followers spread out warm evenly. They aid preserve the best temperature level. Products turn out better.

Safety systems rely on followers. Getting rid of smoke promptly is crucial in a fire. Emergency situation exhaust followers make use of solid shafts. These shafts start quickly and run hard. They clear smoke from getaway paths. Individuals venture out safely.

Company Introduction

Established in 2002, Port of Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Factory Fan Motor shaft

What happens if the fan motor shaft bends?

A bent shaft causes bad vibration. This vibration damages bearings. It makes the fan wobble. Fix it fast. Replace the shaft. Ignoring it ruins the motor.

Why does my fan motor shaft vibrate too much?

Vibration often means imbalance. Dirt buildup on blades is common. Maybe the shaft is bent. Or bearings are worn. Check alignment first. Clean the fan blades. Inspect bearings. Balance the rotor if needed.

Can a motor shaft get too hot? Why?

Yes, overheating happens. Friction causes this. Bad bearings create extra friction. Poor lubrication makes it worse. Misalignment stresses the shaft. Touch the motor housing carefully. Too hot means trouble. Find the friction source quickly.

What materials are best for fan motor shafts?

Steel is standard. Carbon steel is strong and cheaper. Stainless steel fights rust better. Use stainless in wet places. Use carbon steel for heavy loads. Pick the material for your factory’s air and job.

When should I replace the fan motor shaft?

Replace it if bent or cracked. Replace it if grooves are deep. Bad vibration signals replacement. Strange noises mean check it. Heat marks show wear. Don’t wait for failure. Regular checks find problems early.

(Factory Fan Motor shaft)

REQUEST A QUOTE

RELATED PRODUCTS

Cheap GCR15 hardened linear shaft cylinder linear rail

Universal Durable Swing Arm Bushing Middle shaft sleeve back flat fork bushing

mini horizontal/titanium cnc turning milling stainless steel/aluminum parts machine camera shaft turned milled parts

Super Quality Auto Part Spider Front Wheel Rear Axle Shaft Output OEM 3815A140

AE Serious Helical Gears Round Body Planetary Gearbox Output Shaft Without Flange